Are you sure you want to perform this action?

Wheelbuilding

Time and craftmanship

These are the key ingredients for for light and durable wheels. We have been building lightweight wheels for riders around the world for decades. Before they carry you kilometer by kilometer, they go through many hands and have to meet the strictest quality standards. Here you get an insight into our wheelbuilding workflow.

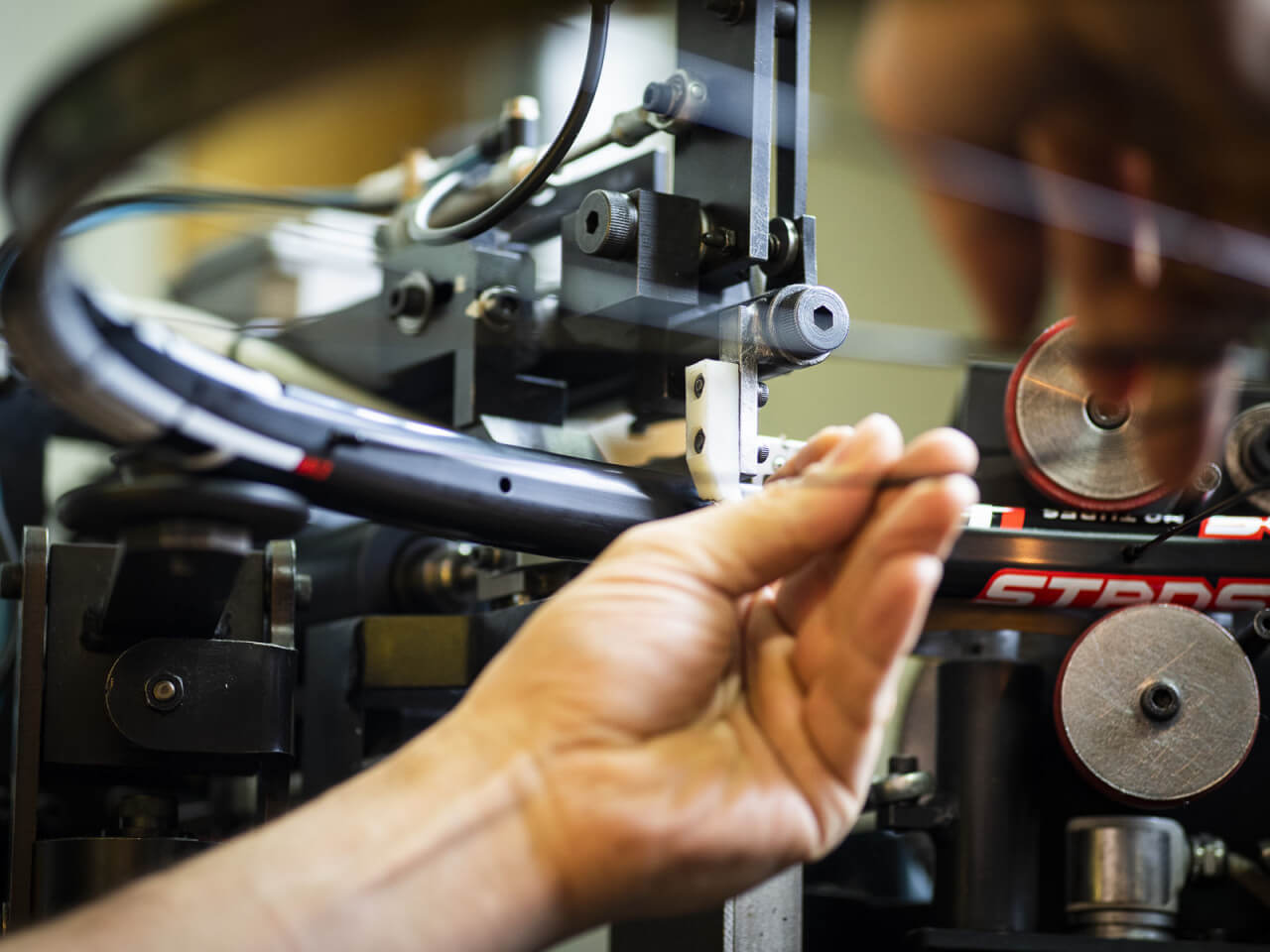

Lacing

Before the wheel takes shape, the selected spokes are threaded into the hub. The correct spoke lengths must be fitted in the appropriate holes. This operation requires a great deal of experience and meticulous work.

Once the hub is laced, the pointed ends of the spokes resemble a hedgehog. This is why we call this stage of the assembly "geigelt", namely, "hedgehoged" in English.

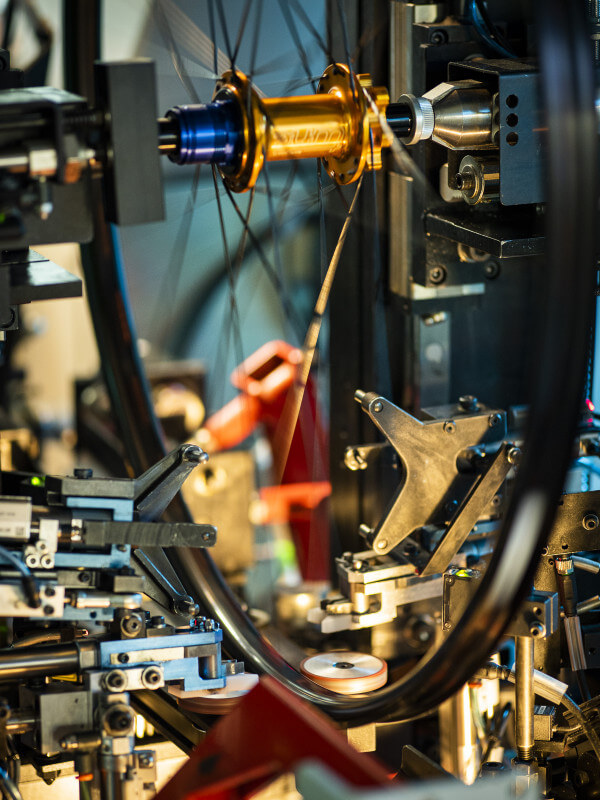

Tensioning and pre-centering

In the next step, the prepared hubs are joined with the rim. A nipple insertion machine accelerates the lacing of the complete wheel.

The machine automatically inserts a nipple into the rim and turns it a few turns onto the spoke. The result is a slightly pre-tensioned wheel which will be pre-centered in the next step.

Centering a wheel is done by slowly and steadily increasing the spoke tension until the wheel forms a rigid unit in torsion.

Depending on the type of wheel the first part of the work is done with a machine but the final centering and adjustment is always done by hand!

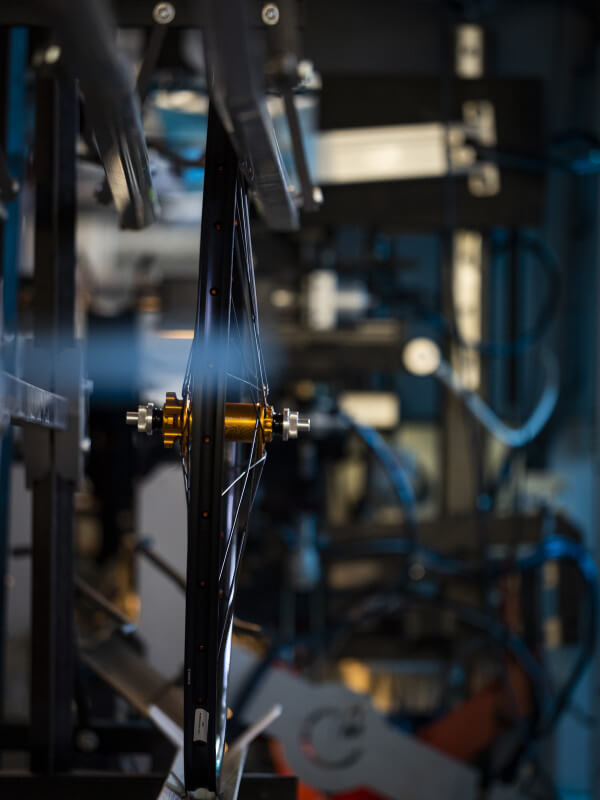

Final centering

At this point the wheel looks ready to the untrained eye. If you look closer you will spot potential for futher refinements.

Our highly skilled employees use all their time and knowledge to perfectly adjust the wheel by hand. They reduce the lateral and radial deviations to a minimum, check the wheel for centricity and relieve any residual stresses on the spokes to make sure they don't lose tension after the first kilometers.

All these steps take time but are well worth it if you are looking for a truly durable and high quality wheelset.

Final quality check

Once the wheel is finished it must undergo our rigorous quality check.

Various criteria are verified using a test protocol. If the wheel meets our high quality standards, the decals are applied and the wheel is ready for shipment.

Our wheels are then sent in boxes specially designed for transporting bicycle wheels. This ensures that they arrive safely at your home!