Early years and breakthrough

The history of Tune begins in 1988. Uli Fahl, born in the Black Forrest, lives now in Munich and works as a chemist for a lubricant manufacturer. He is 35 and on the weekends he goes climbing in the Alps with his wife. He uses his brand new and innovative Kettler aluminium mountain bike to reach the steepest climbing zones. But the MTB with 20kg is far too heavy for Uli and most of the time he is already exhausted after the ride, he needs to save his force to climb, so he starts to experiment.

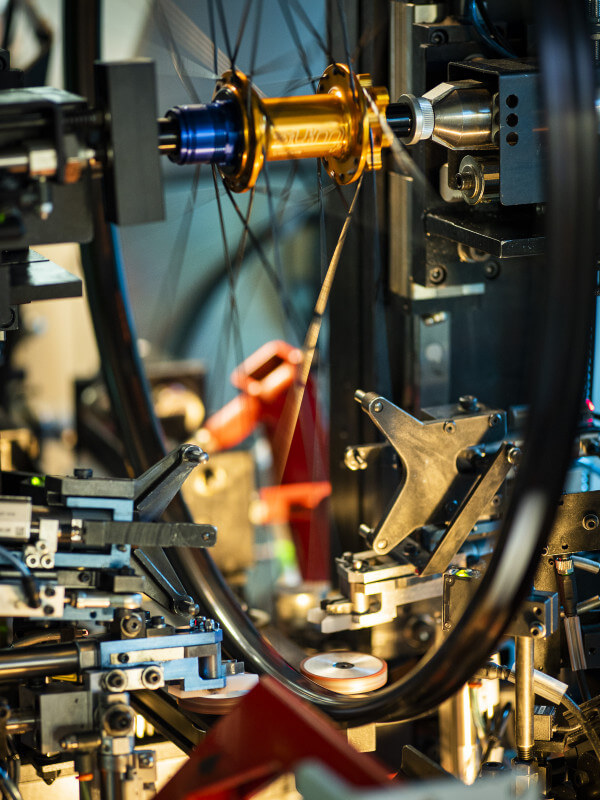

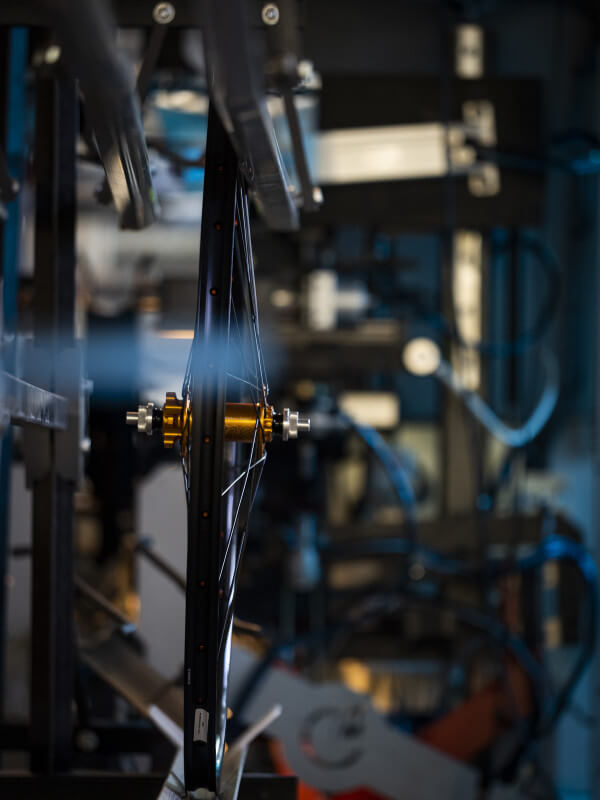

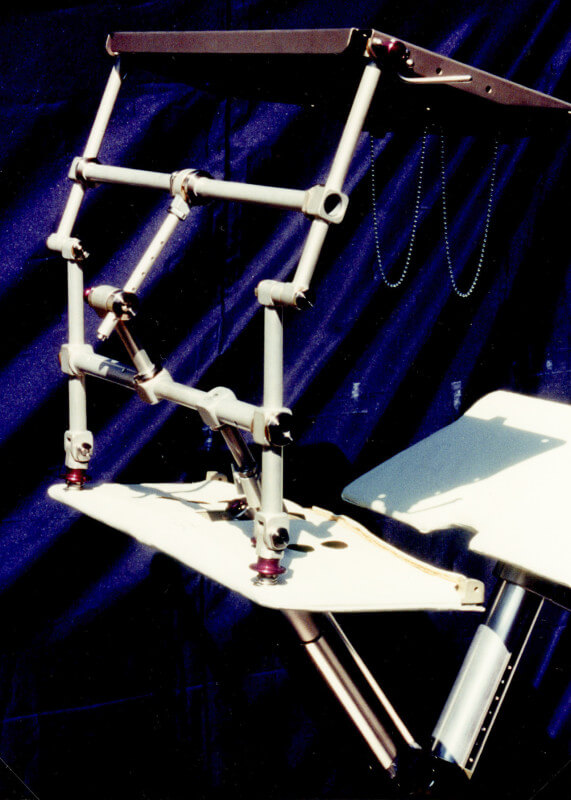

He replaces all screws with aluminum ones and develops weight-optimized rear derailleur kits. They are well received, but he attracts more attention in the professional world with the super-light AC8 quick release system. Anyone who wants to push the weight of their hardtail below the critical mark of 13 kilos orders from Uli. In 1989, the inventor quits his job, starts his company and moves back to the Black Forest. Uli hires people and continues to develop innovative lightweight equipment..