Mother nature

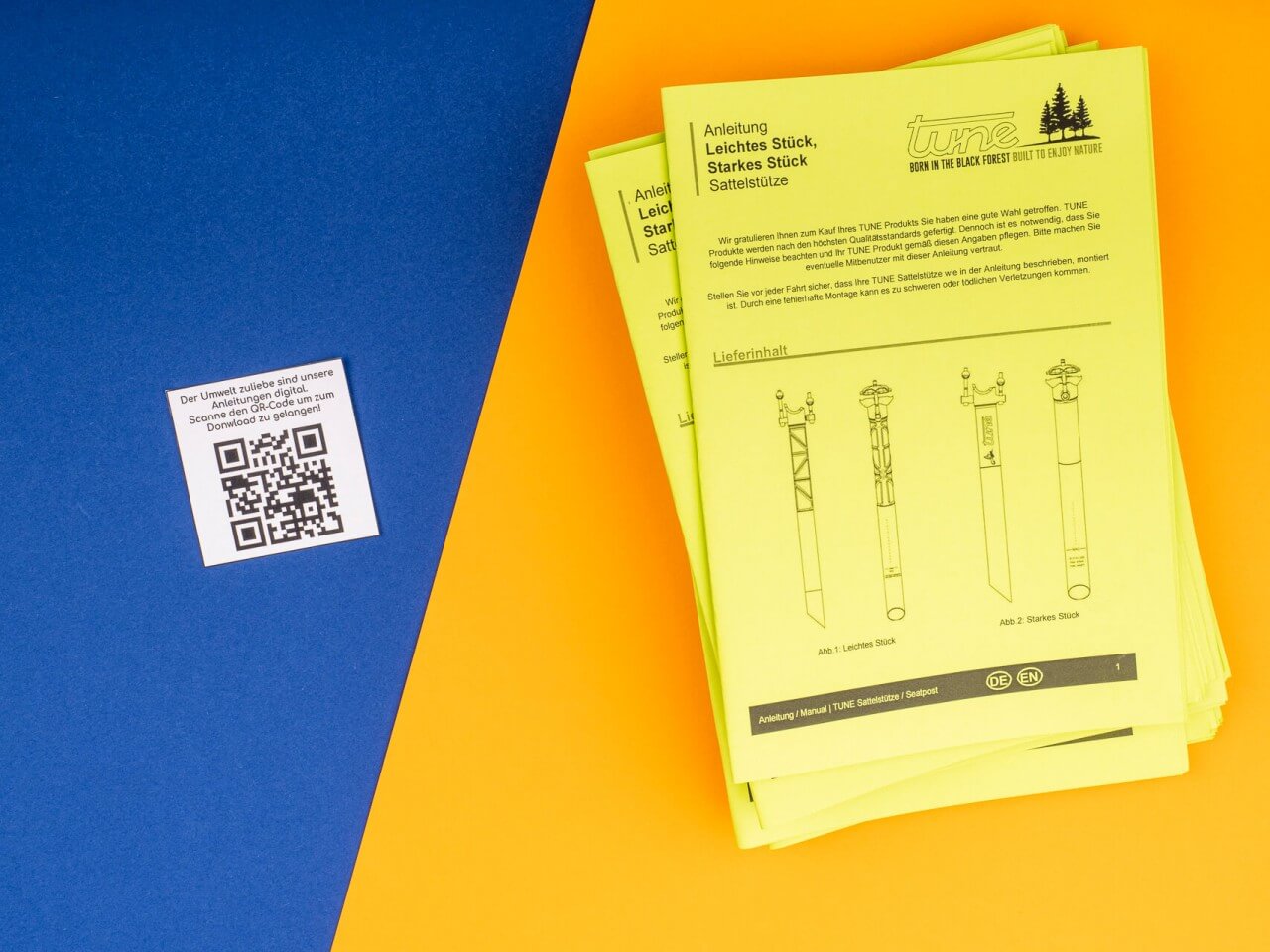

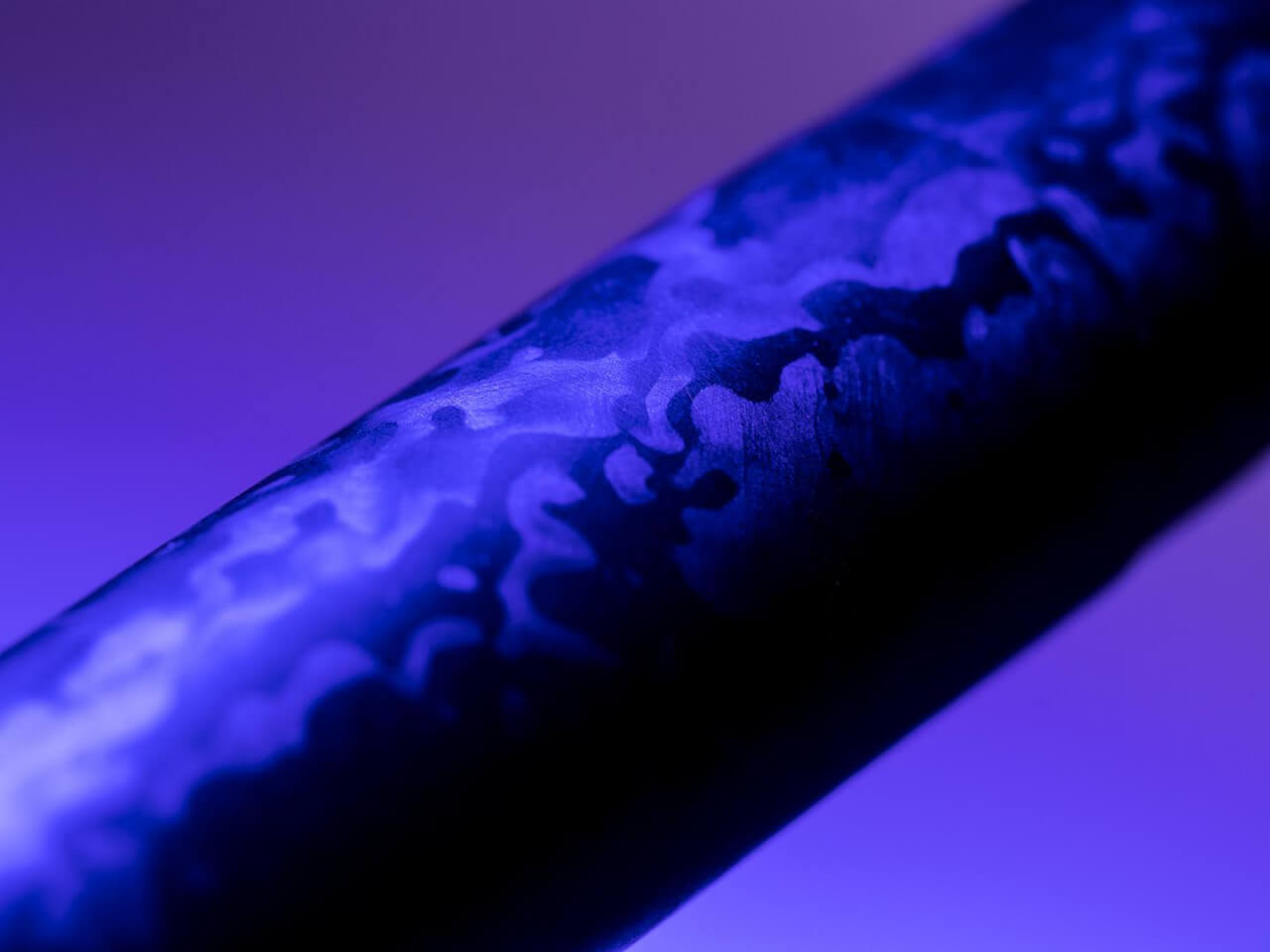

Our roots are in the Black Forest, one of Germanys most beautiful landscapes. We have been located in this area since tune was founded 30 years ago. The close proximity to this beautiful landscape has undoubtedly influenced the products we are known for today.

Our roots are in the Black Forest, one of Germanys most beautiful landscapes. We have been located in this area since tune was founded 30 years ago. The close proximity to this beautiful landscape has undoubtedly influenced the products we are known for today.