Light and durable

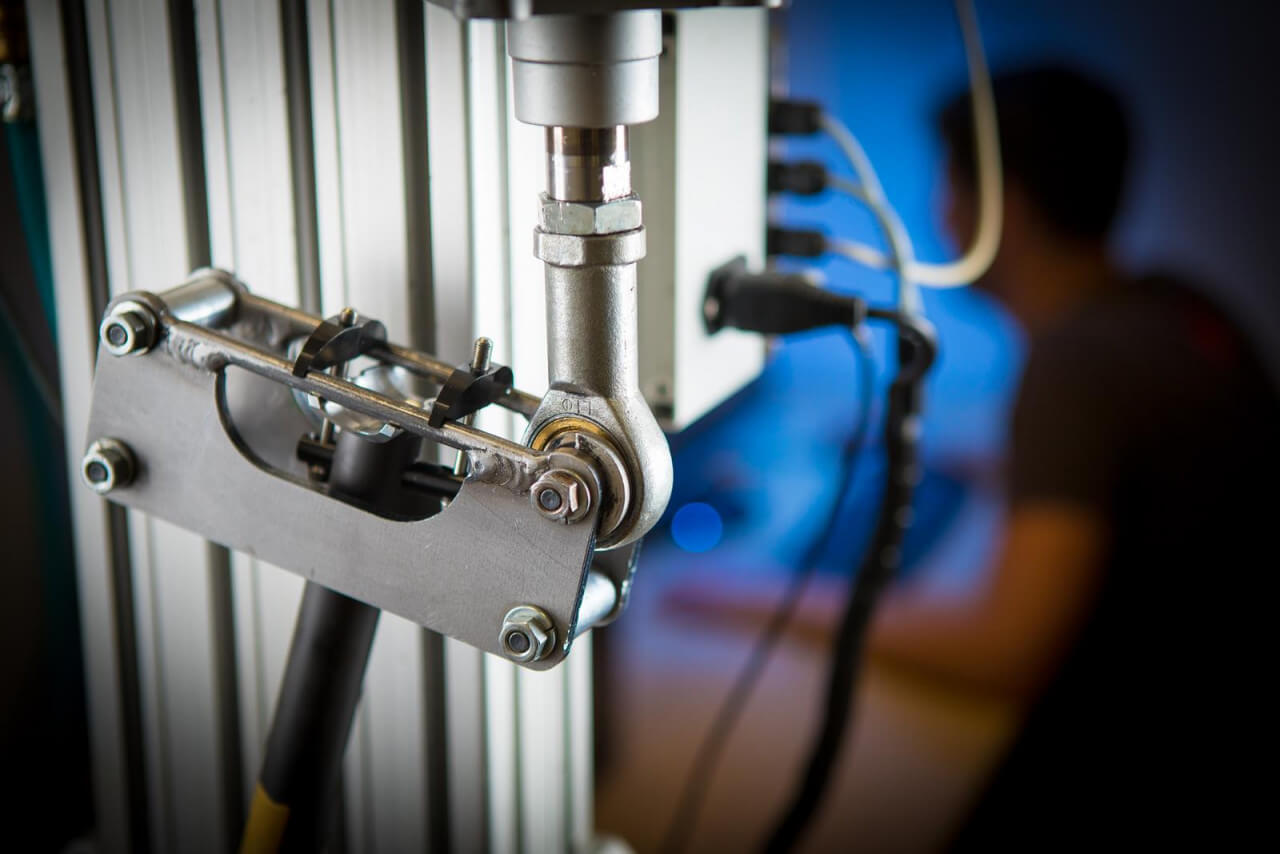

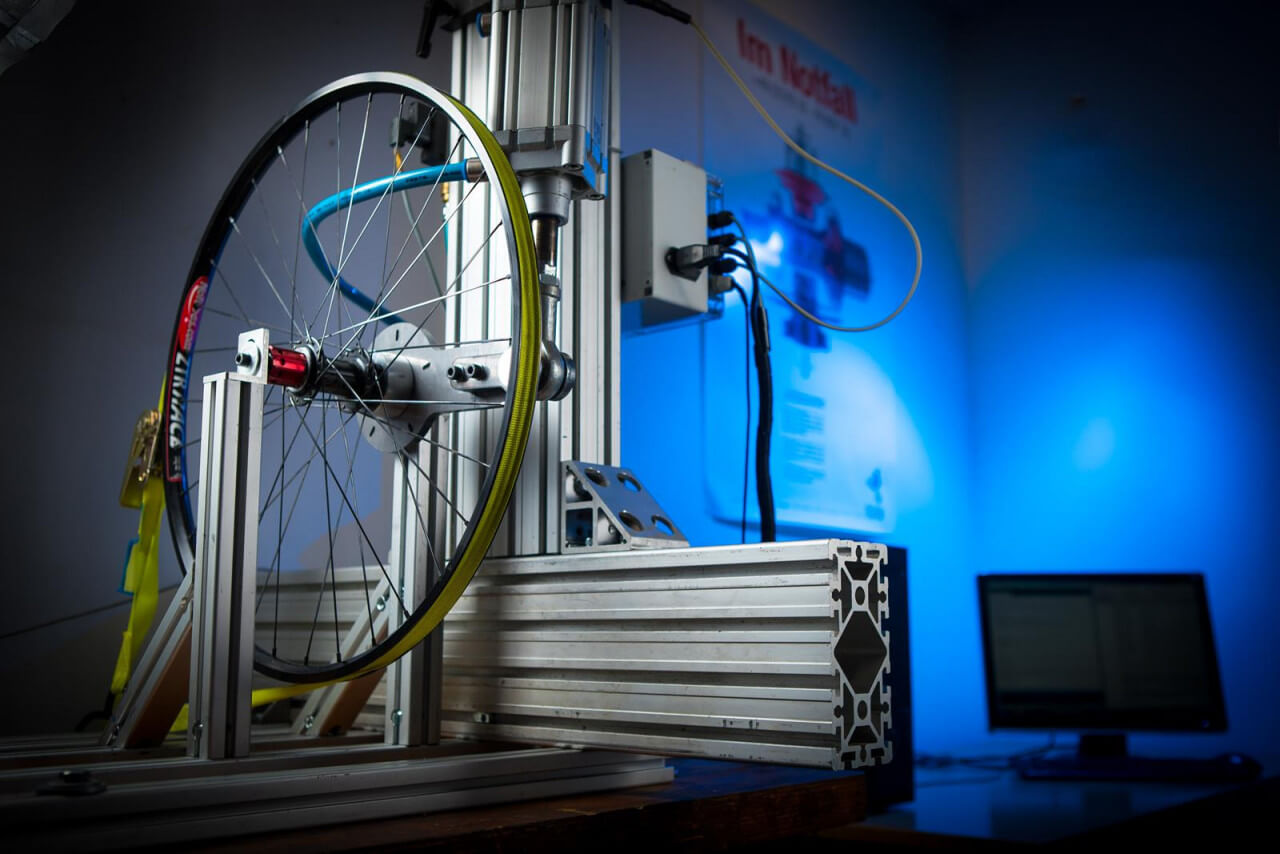

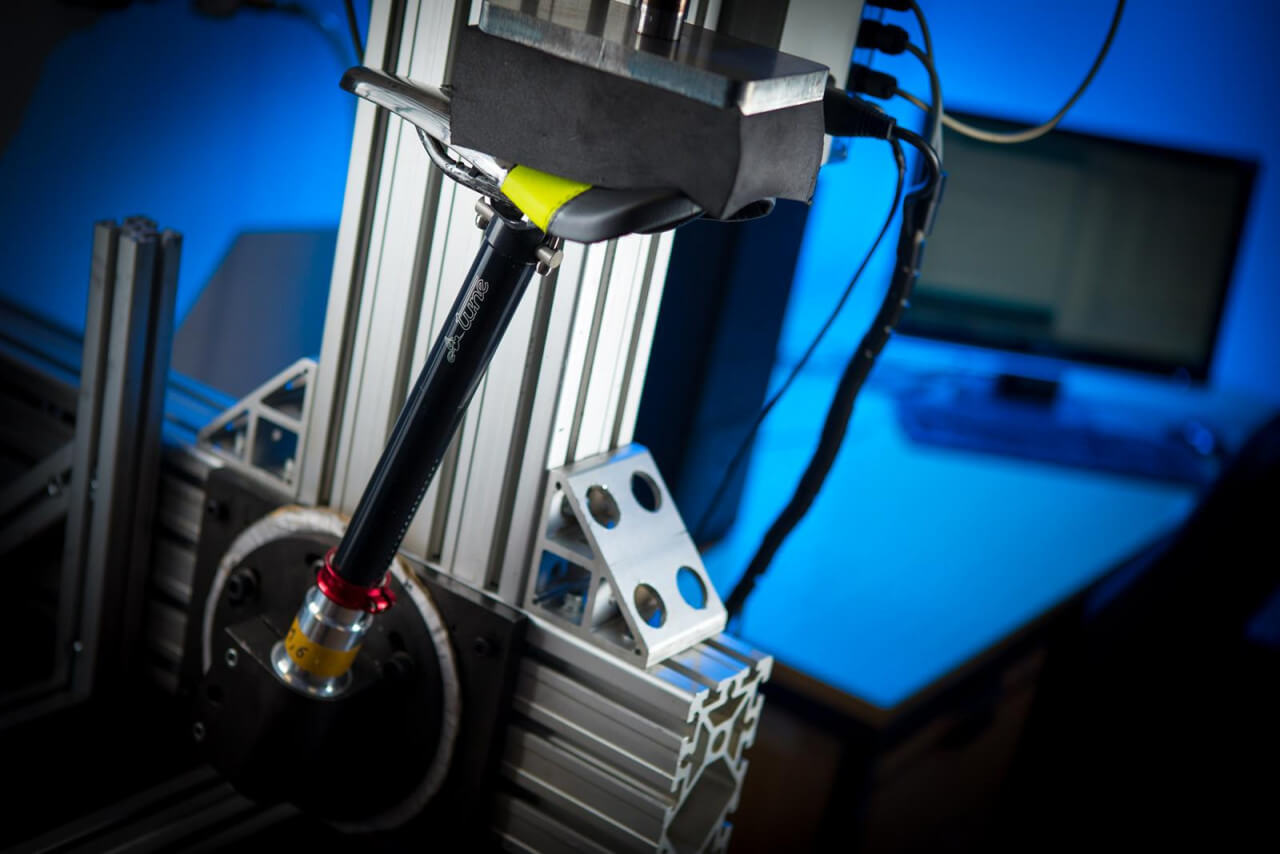

Designing lightweight parts that last is tougher than it seems. During the early concept stage you need to have an eye on even stress distribution and load-optimized shapes. Despite the available modern software there is no way around putting your ideas to the test on a test bench. Only when testing a real part you will finally know what it behaves like when loaded repeatedly. In order to speed up our product development we are equipped with several test benches and can perform almost any test in-house.

Every product goes through a rigorous testing cycle both in the lab and in the real world before becoming available to customers. This means a lot of work for us but also the highest safety standards and many worry-free kilometers for you! We are in the exceptional position to incorporate all steps from prototyping, manufacturing, testing and assembly under one roof which streamlines our processes and helps to offer cutting edge products to our customers.